PRODUCTS &

INNOVATIONS

Products & Innovations

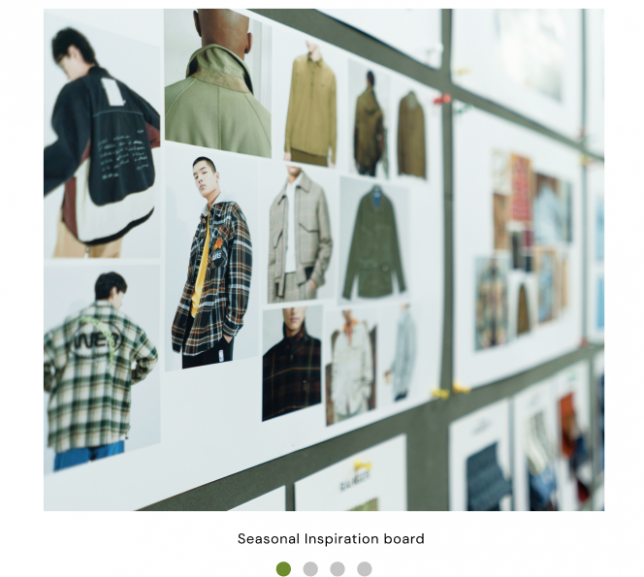

We study market, stay updated on trends and collaborate with suppliers & partners to create new fabric collection. Creating custom solutions for our customers.

Curricular Economy

More fuel-efficient aircraft. More direct and on-time flights. Safer skies and airports. We're found on virtually every commercial, defense and space aircraft.

Energy & Climate

Since 2010, our facilities have implemented more than 4,300 efficiency projects including building automation and controls, lighting and mechanical upgrades, saving more than $80M (annualized).

Operations

Over 100 years ago, we defined energy efficiency by making indoor comfort automatic. Today, we redefine it in 10 million buildings using our technology.

Human Rights

Each year, we keep over half a billion workers safer and more productive with voice-enabled software, barcode scanners, mobile computers and protective equipment.

Conflict Minerals

We pioneered automation control. So we understand complex industrial facilities, and how to create high-quality and high-performance chemicals and materials.

Natural Infrastructure

We provide resources and financial support to causes around the world and encourage employee volunteerism.

Sustainability in Action

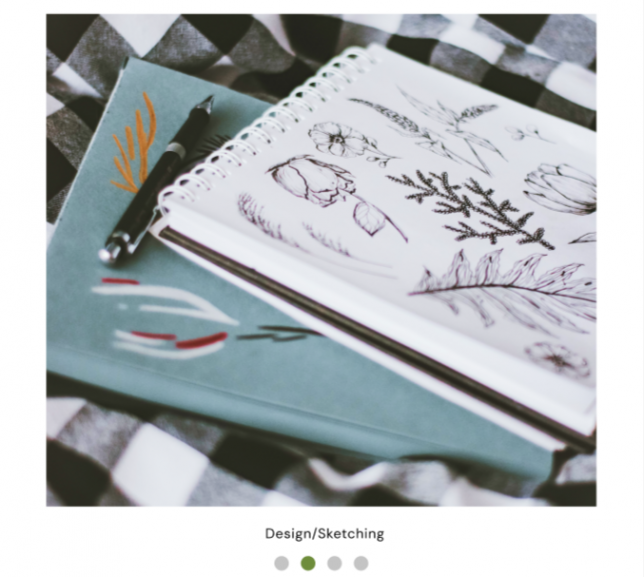

& proto making

creating perfection

Prototyping facility transforms 2D metaphors into 3D, from agility to precision.

We use precise engineering with the latest generation in CADCAM technology. From fabric CAD development to the garment, our methods include new generation CAD software from Tukatech & Gerber along with constantly upgrading digi scanner & state of art auto pattern cutter for next level precision.

Highly qualified garment engineering team ensures error-proof construction methods for product safety & quality achieving compatibility to accessories specific to fabric & styling.